Page 161 - Vestil Catalog 112

P. 161

167

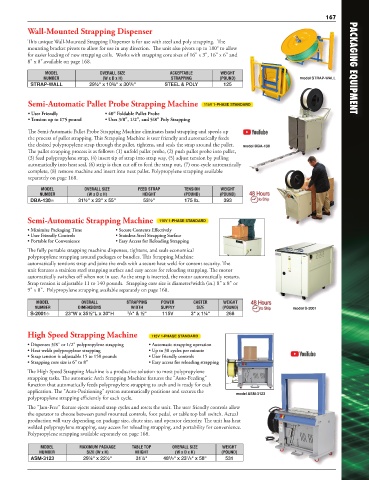

Wall-Mounted Strapping Dispenser

This unique Wall-Mounted Strapping Dispenser is for use with steel and poly strapping. The

mounting bracket pivots to allow for use in any direction. The unit also pivots up to 180° to allow

for easier loading of new strapping coils. Works with strapping core sizes of 16" x 3", 16" x 6" and

8" x 8".available on page 168.

MODEL OVERALL SIZE ACCEPTABLE WEIGHT PACKAGING EQUIPMENT

NUMBER (W x D x H) STRAPPING (POUND) model STRAP-WALL

3

STRAP-WALL 29½" x 10¾" x 30 /8" STEEL & POLY 125

Semi-Automatic Pallet Probe Strapping Machine 115V 1-PHASE STANDARD

• User Friendly • 40" Foldable Pallet Probe

• Tension up to 175 pound • Uses 3/8", 1/2", and 5/8" Poly Strapping

The Semi-Automatic Pallet Probe Strapping Machine eliminates hand strapping and speeds up

the process of pallet strapping. This Strapping Machine is user friendly and automatically feeds

the desired polypropylene strap through the pallet, tightens, and seals the strap around the pallet. model DBA-130

The pallet strapping process is as follows: (1) unfold pallet probe, (2) push pallet probe into pallet,

(3) feed polypropylene strap, (4) insert tip of strap into strap way, (5) adjust tension by pulling

automatically into heat seal, (6) strip is then cut off to feed the strap out, (7) one-cycle automatically

complete, (8) remove machine and insert into next pallet. Polypropylene strapping available

separately on page 168.

MODEL OVERALL SIZE FEED STRAP TENSION WEIGHT

NUMBER (W x D x H) HEIGHT (POUND) (POUND)

DBA-130� 31½" x 23" x 55" 53½" 175 lb. 393

Semi-Automatic Strapping Machine 115V 1-PHASE STANDARD

• Minimize Packaging Time • Secure Contents Effectively

• User Friendly Controls • Stainless Steel Strapping Surface

• Portable for Convenience • Easy Access for Reloading Strapping

The fully portable strapping machine dispenses, tightens, and seals economical

polypropylene strapping around packages or bundles. This Strapping Machine

automatically tensions strap and joins the ends with a secure heat weld for content security. The

unit features a stainless steel strapping surface and easy access for reloading strapping. The motor

automatically switches off when not in use. As the strap is inserted, the motor automatically restarts.

Strap tension is adjustable 11 to 140 pounds. Strapping core size is diameter/width (in.) 8" x 8" or

9" x 8". Polypropylene strapping available separately on page 168.

MODEL OVERALL STRAPPING POWER CASTER WEIGHT

NUMBER DIMENSIONS WIDTH SUPPLY SIZE (POUND) model S-2001

S-2001� 23"W x 35½"L x 30"H 3 /8" & ½" 115V 3" x 1¼" 268

High Speed Strapping Machine 115V 1-PHASE STANDARD

• Dispenses 3/8" or 1/2" polypropylene strapping • Automatic strapping operation

• Heat welds polypropylene strapping • Up to 30 cycles per minute

• Strap tension is adjustable 15 to 150 pounds • User friendly controls

• Strapping core size is 6" to 8" • Easy access for reloading strapping

The High Speed Strapping Machine is a productive solution to most polypropylene

strapping tasks. The automatic Arch Strapping Machine features the "Auto-Feeding"

function that automatically feeds polypropylene strapping to arch and is ready for each

application. The "Auto-Positioning" system automatically positions and secures the model ASM-3123

polypropylene strapping efficiently for each cycle.

The "Jam-Free" feature ejects missed strap cycles and resets the unit. The user friendly controls allow

the operator to choose between panel mounted controls, foot pedal, or table top ball switch. Actual

production will vary depending on package size, chute size, and operator dexterity. The unit has heat

welded polypropylene strapping, easy access for reloading strapping, and portability for convenience.

Polypropylene strapping available separately on page 168.

MODEL MAXIMUM PACKAGE TABLE TOP OVERALL SIZE WEIGHT

NUMBER SIZE (W x H) HEIGHT (W x D x H) (POUND)

1

3

ASM-3123 29¼" x 22½" 31½" 48 /8" x 23 /8" x 58" 531